Services

All our developments include safety!

At Synergy Mechatronics, functional safety is not an "extra" or an additional cost: it is an integral part of every project. Thanks to our functional safety certification, all our developments incorporate risk analysis and the necessary solutions to comply with current regulations from the design stage onwards.

Today, risk analysis cannot be optional. It must be an essential element in the design of any modern machine, ensuring safe operation, production continuity, and personnel protection.

At Synergy, we are clear about one thing:

safety is not negotiable; it is integrated from the outset

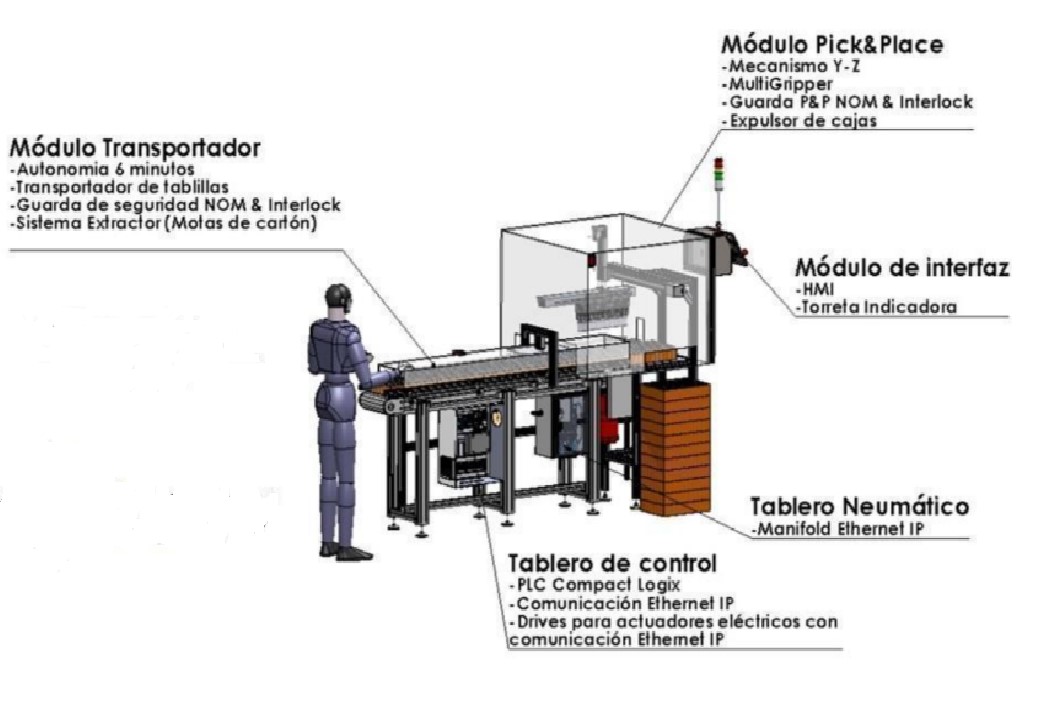

Mechanical design and machine manufacturing

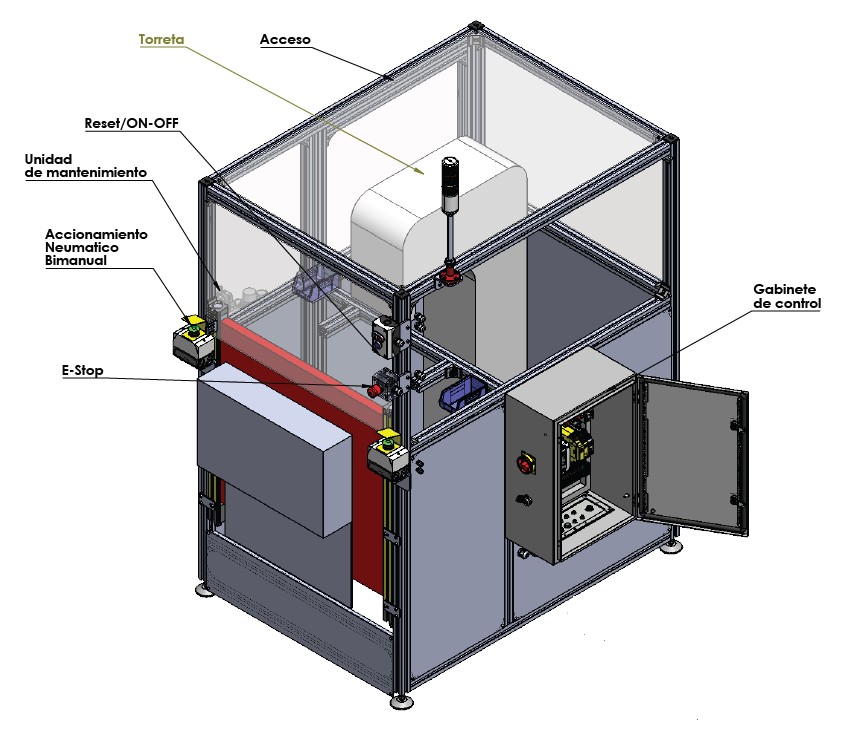

With over 12 years of experience, at Synergy Mechatronics we specialize in the mechanical design, manufacturing, integration, and commissioning of automation equipment, always starting from a deep understanding of the customer's needs and the actual operating environment.

Our process begins with an on-site survey, where we analyze the problem, physical constraints, workflow, ergonomics, and safety conditions. Based on this information, we develop the initial conceptualization, evaluating different solution alternatives and selecting the most efficient and robust option for the process.

We then move on to the detailed design, where we define materials, tolerances, joints, mechanisms, sensors, and auxiliary systems, ensuring the manufacturability and maintainability of the equipment.

To do this, we use professional 3D modeling software (such as SolidWorks, Inventor, and NX), which allows us to:

> Visualize and validate the design before manufacturing

> Detect interference and collisions

> Optimize assembly and maintenance times

> Reduce errors in production and commissioning

> Increase system productivity and reliability

We develop solutions ranging from stand-alone stations and robotic cells to complete manufacturing and assembly lines, primarily serving the following sectors:

> Automotive

> Consumer goods

> Pharmaceutical

> Personal care

> Food and beverages

Our focus is on operational efficiency, functional safety, and added value, delivering equipment that operates stably, safely, and with measurable results in productivity.

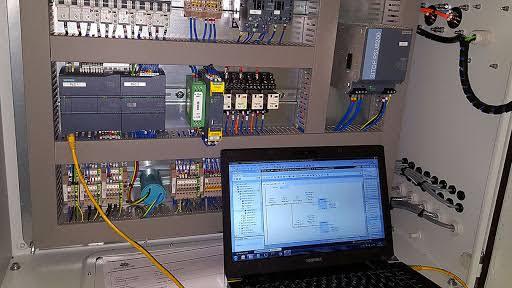

Electrical design and PLC & HMI programming

At Synergy Mechatronics, we offer comprehensive solutions in electrical design and control system integration, covering everything from engineering to plant commissioning. Our process begins with the sizing of the electrical system according to operational requirements, current regulations, and load analysis, ensuring a robust and safe architecture.

We create 2D electrical diagrams using industry standards and IEC/NFPA symbols, ensuring clear, organized, and easy-to-maintain documentation. This includes:

-

Power and control schematics

-

Input/output diagrams (I/O List)

-

Cabinet layout plans

-

Industrial network diagrams (EtherNet/IP, Profinet, IO-Link, etc.)

We manufacture custom control cabinets, taking into account:

-

Adequate heat dissipation and IP/NEMA protection

-

Cable routing and organization to facilitate maintenance

-

Selection of highly reliable components (Siemens, Allen-Bradley, Schneider, Omron, etc.)

In the field of automation, we develop advanced PLC and HMI programming, using modular architecture techniques, assisted diagnostics, and structured programming (ST, LAD, FBD, and SCL), which allows us to:

-

Reduction in cycle times

-

Easy system scalability

-

Intuitive and secure graphical interfaces for the operatorr

-

Implementation of alarms, recipes, trends, and real-time analysis

In addition, we integrate Industry 4.0 technologies such as remote monitoring, data collection, traceability, and connectivity to MES/SCADA systems for information-based decision making.

The result: reliable, efficient control systems that are ready for modern operation.

Contact us to schedule a visit to your plant so we can help you specify your project.

Comissioning and maintenance

At Synergy Mechatronics, we offer a comprehensive service for the installation of equipment and production lines, ensuring that each project is planned and executed with precision from the engineering stage onwards. We carry out studies of layout, process flow, capacity, internal logistics, and industrial safety to guarantee that the installation integrates efficiently into the existing production system.

We apply Industry 4.0 principles to our preventive and corrective maintenance services, incorporating smart monitoring, predictive failure analysis, and equipment history traceability. This helps us minimize unscheduled downtime, increase machinery availability, and extend its useful life.

Our services cover both electrical and mechanical areas, with activities that include:

-

Leveling, alignment, and structural anchoring of equipment.

-

Electrical, pneumatic, and hydraulic connections in compliance with regulations.

-

Power-up and commissioning, ensuring optimal operating conditions from day one.

-

Digitization of maintenance through records, indicators, and dashboards for decision-making.

Our approach ensures operational reliability, efficiency, and safety, aligning your plant with advanced manufacturing standards.

Contact us for a visit to your plant so we can help you specify your project.

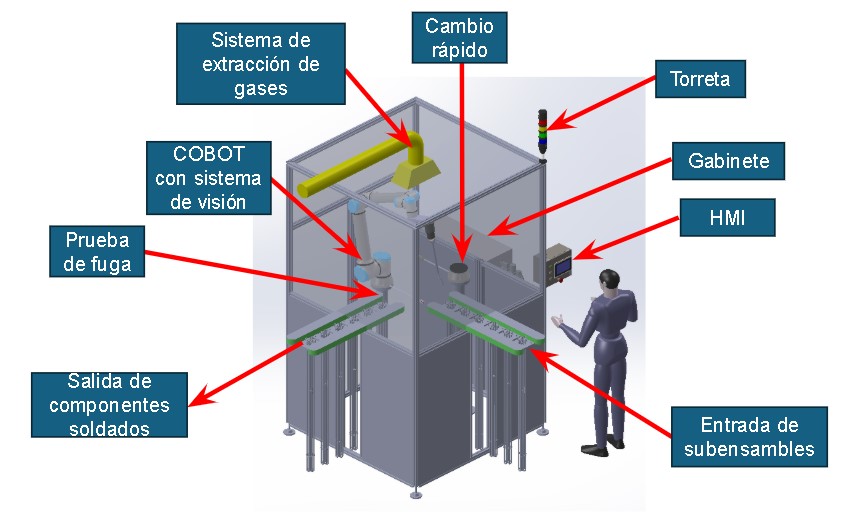

Fixture design and manufacturing

At Synergy Mechatronics, we design and manufacture a wide range of mechanical and mechatronic fixtures for assembly, welding, and verification applications within the automotive industry, ensuring precision, repeatability, and durability in every solution.

Types of fixtures we develop:

-

Assembly fixtures:

Devices designed to hold and position components correctly during the joining process, preventing variations and ensuring precise alignment between parts.

-

Welding fixtures:

Used to hold parts in the correct position during MIG, TIG, laser, or spot welding processes. They guarantee dimensional tolerances and reduce thermal deformation.

-

Inspection or verification fixtures (Go/No-Go):

Equipment that allows critical dimensions or functional characteristics of finished parts to be checked, ensuring that they meet established quality standards.

-

Mechatronic fixtures:

Systems that integrate sensors, actuators, and controls to automate functions such as clamping, positioning, functional testing, or calibration of parts.

-

Functional testing fixtures (EOL):

Benches designed to validate the electrical, pneumatic, or mechanical operation of a component before it is released to the production line or shipment.

Contact us for a visit to your plant so we can help you specify your project.

Risk analisys, verification, validation and safety remediation

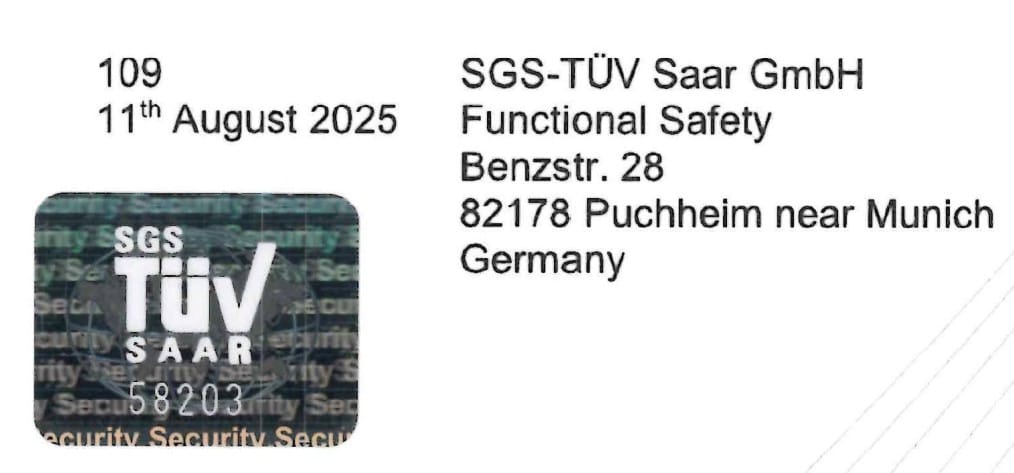

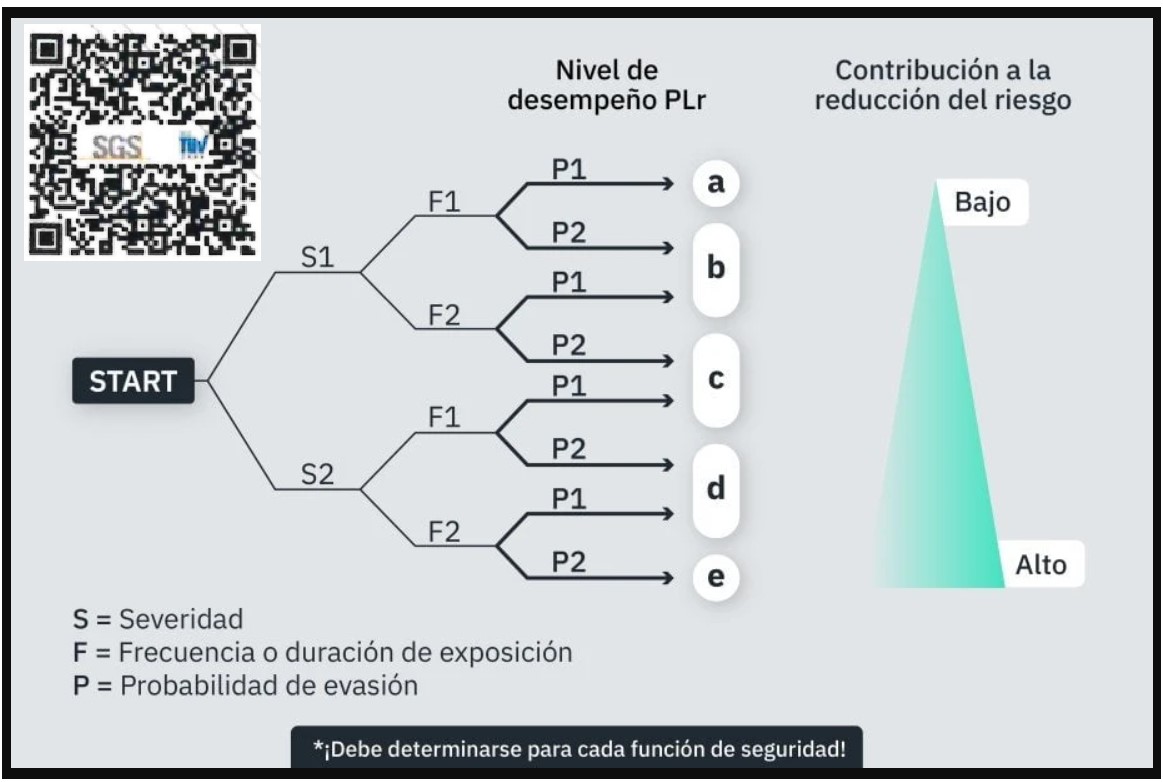

At Synergy Mechatronics, we are TÜV certified as a qualified company for functional safety validation in machinery and production lines. This recognition supports our ability to evaluate, document, and bring your equipment to a Safe Machine status, complying with international standards such as ISO 12100 (Risk Analysis) and ISO 13849-1 (Safety in Control Systems).

Risk management is a fundamental step for any industrial plant: it allows you to identify hazards, assess the probability and severity of damage, and establish the necessary measures to protect operators, minimize unscheduled downtime, and ensure the integrity of the production process.

Based on the results of the risk analysis, we develop safety remediation plans, which may include:

-

Design and manufacture of physical guards and shields (fixed and mobile).

-

Integration of interlocks, light curtains, and emergency stop systems.

-

Improvement or upgrade of safety architecture in PLCs and safety relays.

-

Documented functional validation, backed by technical evidence and test protocols.

Contact us to arrange a visit to your plant so we can help you specify your project.

Precision machining, tooling and spare parts service

At Synergy Mechatronics, we have a highly specialized machining workshop where we manufacture precision components and solutions with quality standards that meet the demands of the Mexican and international industries. Our focus is on dimensional excellence, repeatability, and reliability in every part.

In addition to producing our own components for automation projects, we offer machining services for special parts, from simple geometries to highly complex components, guaranteeing the tolerances, finishes, and specifications required by the customer

Manufacturing capabilities:

> Conventional milling machines (x9)

> Conventional lathes (x3)

> Precision grinding machine

> 3D printing and laser engraving

> Optical comparator for quality control

> CNC machining center (turning and milling)

> Surface finishing of parts (nickel plating, zinc plating, bluing)

> Placarbonate and alucubond cutting

> Electrostatic painting

We can manufacture parts and spare parts from plans or models provided by the customer, or offer a complete custom engineering and design service, from conceptualization to final delivery.

Contact us to schedule a technical visit and help you specify your project or machining requirements

.For more information, download our brochure of services.

Download our e-book about Industry 4.0 in Mexico.

https://www.amazon.com.mx/INDUSTRI4-0-INTEGR4CI%C3%93N-4-M%C3%89XICO-Spanish/dp/B095GLRSBM/ref=tmm_pap_swatch_0?_encoding=UTF8&qid=&sr=

Online store

Visit our online store for industrial components.